In-Wheel Motor Technology: Driving the Future

As the wave of electrification sweeps the globe, technologies that maximize energy efficiency are in high demand. Among them, “in-wheel motor” technology is attracting attention as an innovative technology that overturns the common sense of conventional drive systems.

As the name suggests, in-wheel motor technology involves mounting motors directly inside the wheels of a vehicle. This groundbreaking technology eliminates the need for conventional drive components such as engines and transmissions, dramatically increasing design freedom. With independent control of each wheel, it expands the possibilities of mobility, including improved energy efficiency, enhanced driving stability, and maximized space utilization.

In-wheel motors are broadly classified into two types: “geared” and “gearless.” It is important to understand the characteristics of each type and select the optimal type for the application.

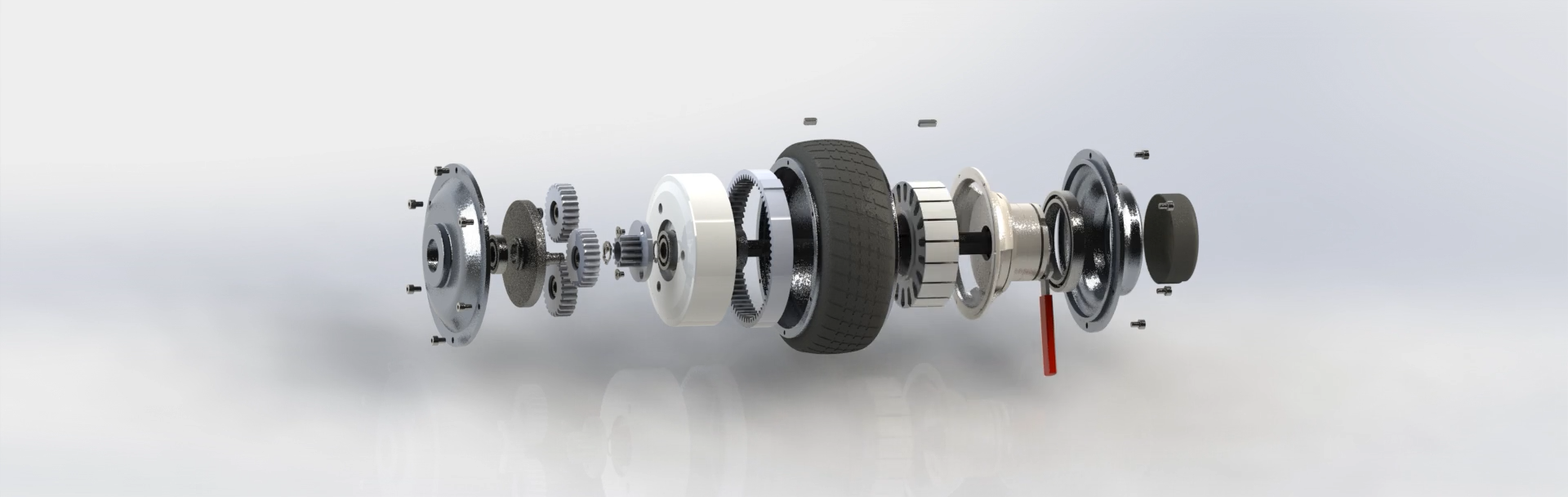

Geared In-Wheel Motors

・Structure and Mechanism

- Geared in-wheel motors have an integrated motor and reducer structure, transmitting the motor’s rotational force to the tires through the reducer. This gear mechanism reduces the motor’s rotational speed while amplifying torque. Especially in the low-speed range, it enables powerful acceleration performance and provides stable power even when climbing hills or carrying heavy loads.

・Advantages

- High Torque: By utilizing the gear reduction ratio, it generates powerful torque that cannot be achieved by the motor alone.

- Excellent Low-Speed Performance: High torque enables powerful acceleration, particularly at start-up and on steep hills.

- Improved Efficiency: The use of a reducer allows for efficient operation while suppressing motor rotation speed, optimizing energy consumption.

・Disadvantages

- Structural Complexity: Inclusion of the gear mechanism makes the structure more complex, potentially increasing manufacturing costs and weight.

- Maintenance: Periodic maintenance may be required due to wear and tear on gear components.

Gearless In-Wheel Motors

・Structure and Mechanism

- Gearless in-wheel motors have a simple design that transmits the motor’s rotational force directly to the tires without using gears or reducers. This direct drive method simplifies the structure and achieves weight reduction. Moreover, as there is no energy loss due to gears, efficient driving is possible, especially in the low-speed range.

・Advantages

- Weight Reduction: The absence of gear mechanisms makes the motor itself lightweight, reducing the overall vehicle weight.

- Simple Structure: Simple structure leads to lower failure risk and allows for highly reliable design.

- Quietness: The absence of gears eliminates mechanical noise, providing quiet driving.

・Disadvantages

- Torque Limitations: Torque may be lower compared to geared motors due to the absence of gears. Power shortage may be felt, especially with heavy vehicles or on hills.

- Speed-Dependent Efficiency: Efficiency tends to decrease in the high-speed range, making it unsuitable for long-distance highway driving.

DRIPS’s Geared In-Wheel Motor

DRIPS’s geared in-wheel motor boasts superior performance unmatched by other companies, leveraging years of technological development and accumulated experience. In particular, its significant strength lies in achieving quietness during driving while maintaining high torque.

This allows DRIPS’s in-wheel motor, which balances quietness and power, to provide customers with a comfortable and stress-free driving experience.

Contact Us

DRIPS leverages its technology and expertise cultivated through experience with partners in various fields, including mobility, robotics, and agricultural machinery, to provide optimal in-wheel motor solutions tailored to customer needs.

We will sincerely address your requests, including technical inquiries and consultations on selecting the most suitable motor for your project.

Please use the “Inquiry Form” to contact us. The latest information on DRIPS in-wheel motors and product lineup is constantly updated on our website.